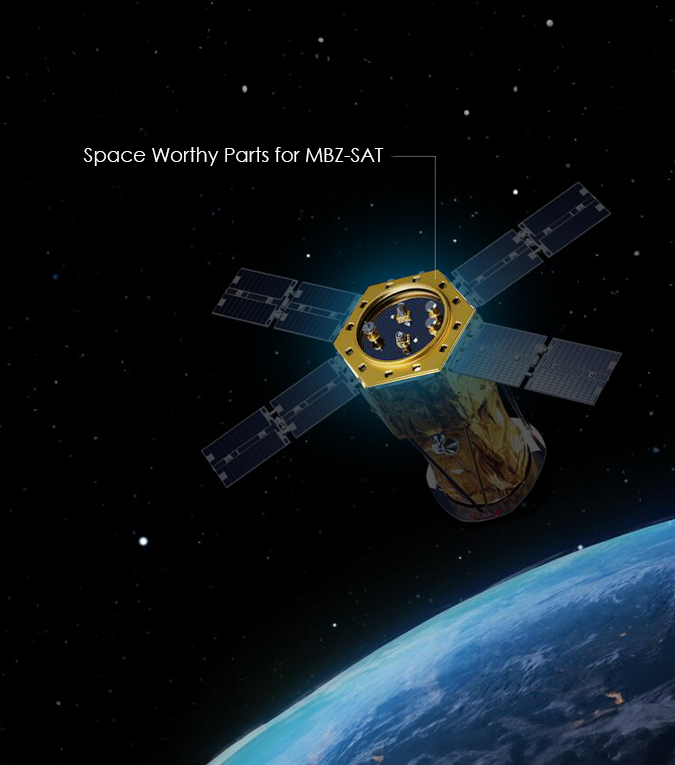

Built to spec, verified

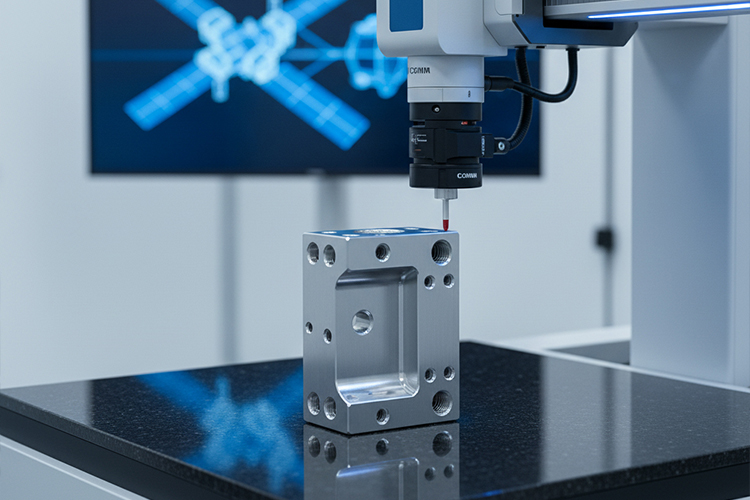

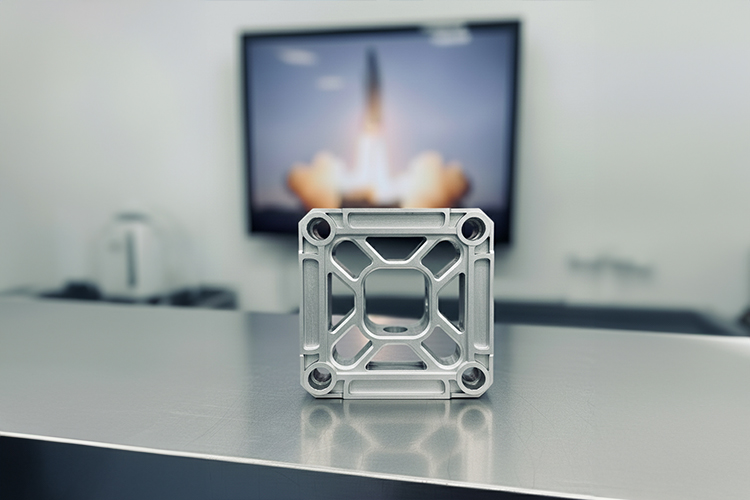

Small details (edge control, feature integrity, coating thickness) drive first-time fit.

Documentation reduces rework and audit risk.

• PPAP/FAI packages with ballooned drawings and results.

• Process capability checks on critical features (GD&T + CMM).

• Sprint slots for urgent builds and changeovers